La industria textil es un sector muy activo que depende en gran medida de diversos equipos y maquinaria para producir tejidos, prendas de vestir y otros productos textiles. Entre estos equipos fundamentales se encuentran los compresores de aire, que desempeñan un papel importante en el suministro de aire comprimido para una amplia gama de aplicaciones. En este artículo, exploraremos la importancia de los compresores de aire en la industria textil y cómo son esenciales para garantizar la eficiencia, la productividad y la calidad en los procesos de producción textil.

El papel de los compresores de aire en la industria textil

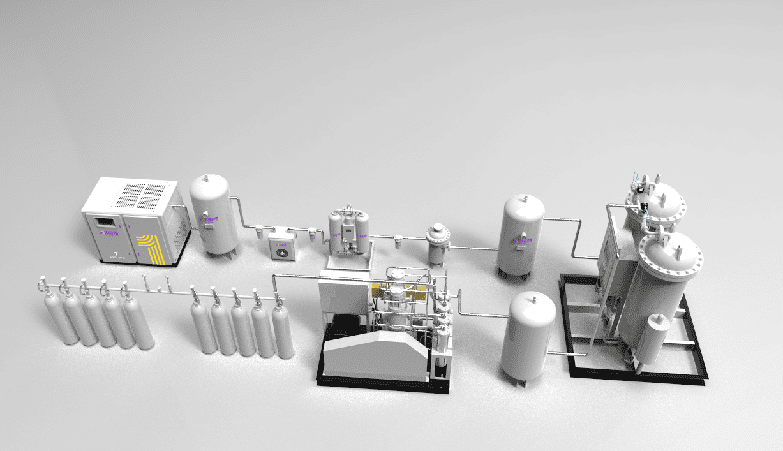

Los compresores de aire son vitales en la industria textil para accionar numerosas herramientas y equipos neumáticos. Generan y suministran aire comprimido a una presión constante, esencial para controlar los movimientos de diversos componentes de las máquinas textiles. Algunas de las principales aplicaciones de los compresores de aire en la industria textil son

a. Proceso de hilatura: Los compresores de aire suministran aire comprimido a las máquinas de hilar, controlando procesos como el estiraje, la torsión y el bobinado, garantizando una producción de hilo de alta calidad.

b. Proceso de tejido: En las máquinas de tejer, los compresores de aire accionan los dispositivos de chorro de aire y pinzas, facilitando un tejido preciso y eficaz.

c. Impresión y teñido: Los compresores de aire son fundamentales en los procesos de impresión y teñido, ya que proporcionan aire comprimido para el funcionamiento de las máquinas de teñido y los equipos de impresión.

d. Limpieza y secado: Los compresores de aire se utilizan para soplar aire para limpiar fibras, tejidos y superficies de maquinaria, así como para secar productos acabados.

Eficiencia y ahorro energético

En la competitiva industria textil actual, la eficiencia es crucial para mantener una ventaja competitiva. Los compresores de aire energéticamente eficientes están diseñados para optimizar la producción de aire y reducir el consumo de energía. Características como los variadores de velocidad (VSD) y los sistemas de control inteligentes garantizan que el compresor funcione a la capacidad necesaria, evitando el derroche innecesario de energía.

Fiabilidad y reducción del tiempo de inactividad

Los tiempos de inactividad imprevistos pueden resultar costosos para los fabricantes textiles. Elegir compresores de aire fiables y robustos de fabricantes reputados puede ayudar a minimizar el tiempo de inactividad y garantizar una producción continua. El mantenimiento regular y el servicio oportuno son esenciales para mantener los compresores en condiciones óptimas de funcionamiento.

Calidad y coherencia

Los compresores de aire desempeñan un papel vital en el mantenimiento de una presión de aire constante, garantizando una calidad uniforme del producto y reduciendo las variaciones en la producción. Esta uniformidad es especialmente crucial en procesos como el teñido y la estampación, donde se requiere un control preciso.

Reducción del ruido y consideraciones medioambientales

En las fábricas textiles, donde funcionan numerosas máquinas, los niveles de ruido pueden ser una preocupación para el bienestar de los trabajadores. Los compresores de aire con funciones de reducción de ruido y un aislamiento acústico adecuado pueden crear un entorno de trabajo más propicio y cómodo.

Personalización y adaptabilidad

Cada instalación de producción textil tiene unos requisitos únicos. Los compresores de aire ofrecen flexibilidad en términos de personalización y adaptabilidad para satisfacer necesidades específicas, garantizando el mejor rendimiento posible para cada proceso.

La industria textil depende en gran medida de los compresores de aire para impulsar la productividad, la calidad y la eficiencia en diversos procesos de producción. Desde la hilatura y el tejido hasta el teñido y la estampación, los compresores de aire impulsan operaciones críticas que permiten la creación de textiles de alta calidad. La elección del compresor de aire adecuado, teniendo en cuenta factores como la eficiencia, la fiabilidad, la reducción del ruido y la personalización, puede influir significativamente en el rendimiento general de las instalaciones de producción textil. Al invertir en compresores de aire de alta calidad y garantizar un mantenimiento regular, los fabricantes textiles pueden mejorar sus operaciones y seguir siendo competitivos en el dinámico mercado textil.