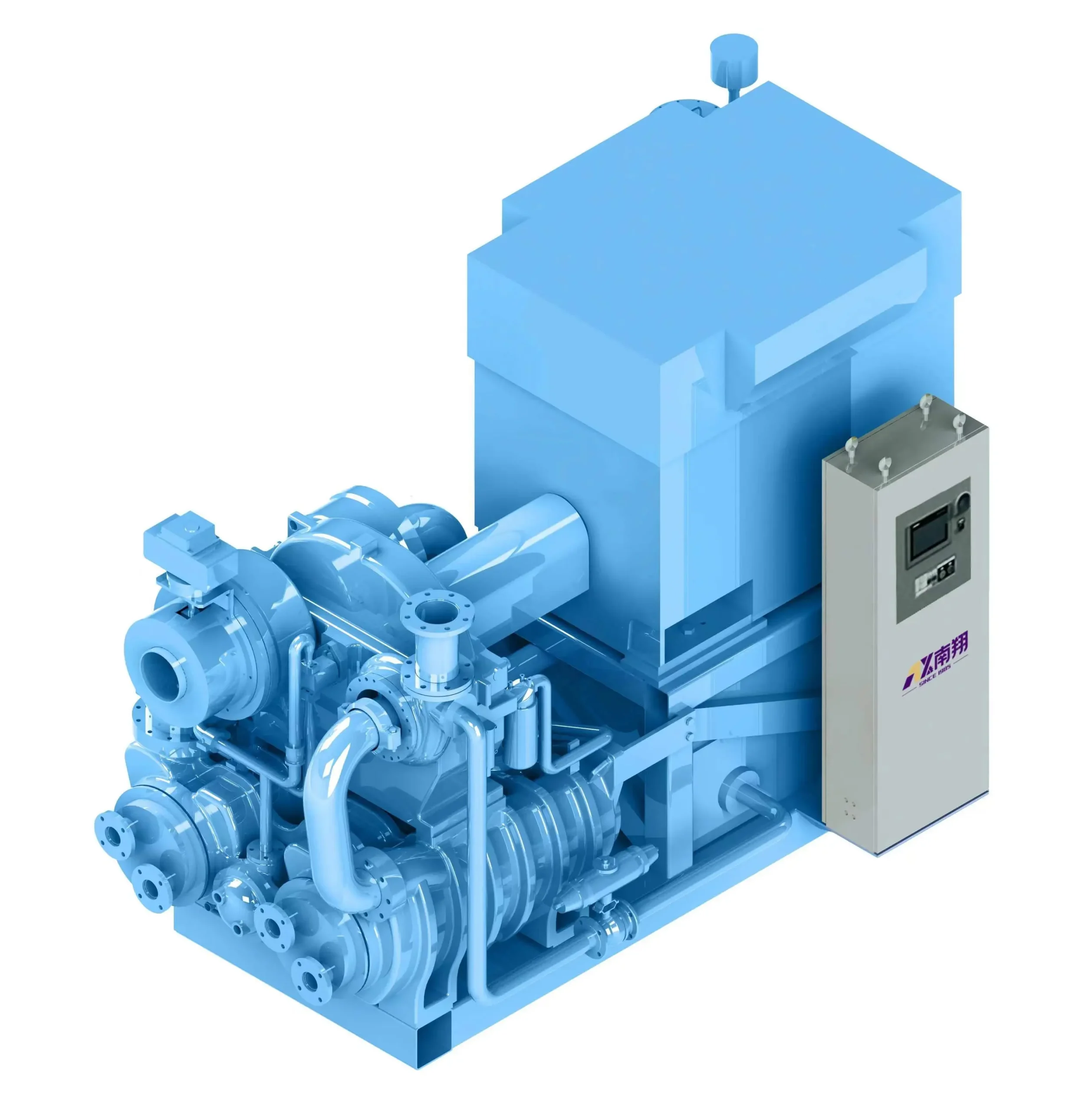

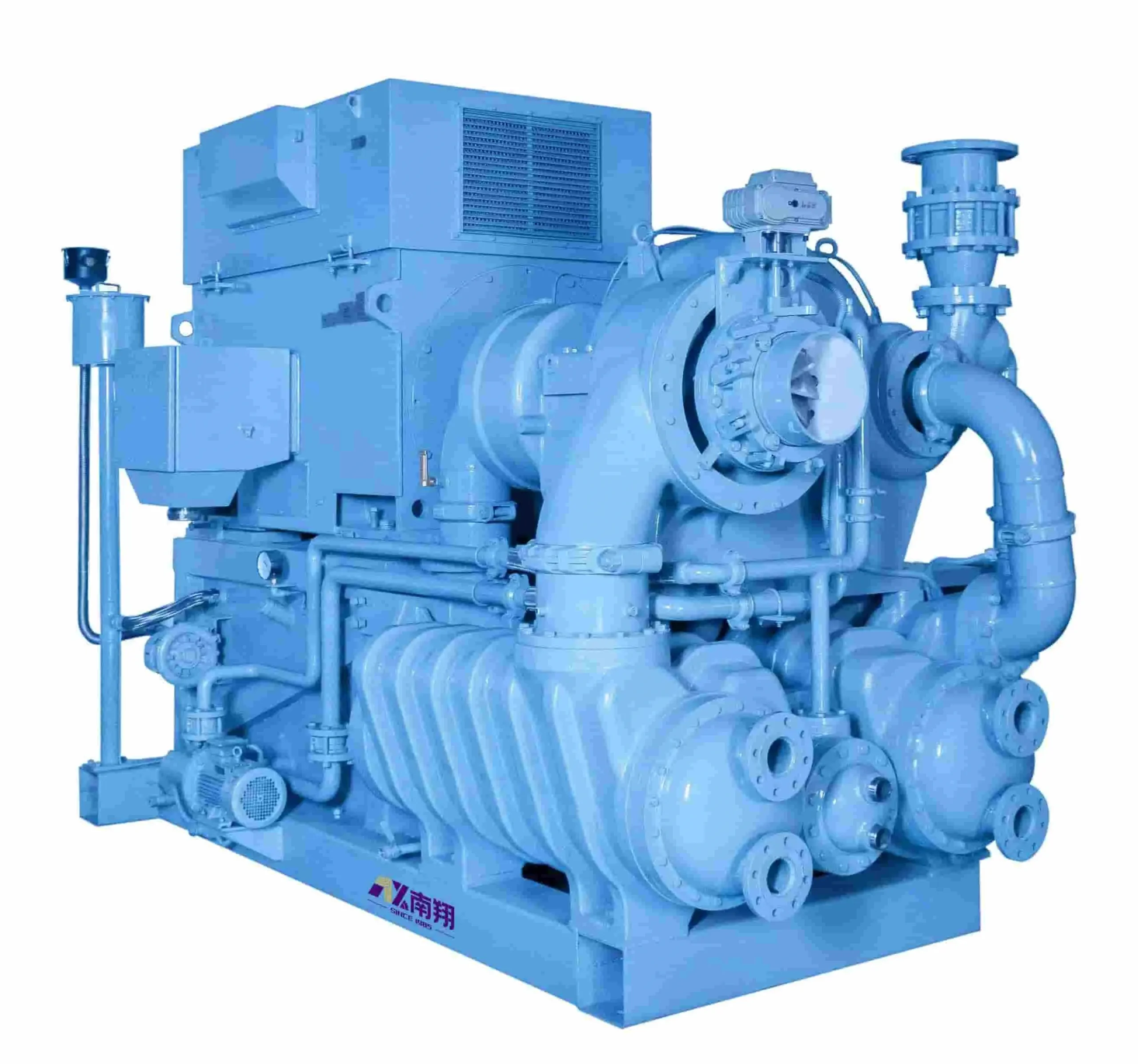

Compressori d'aria centrifughi

Compressori d'aria centrifughi

Rpressione: 0.6-30 bar, 8.7-435 psi

Flusso d'aria in uscita: 24-3000 m³/min, 848-105944 cfm

Potenza: 132-15130 kW, 177-20274 hp

Features of the Centrifugal Air Compressors

● High reliability, high safety

● Integrated package and economical installation

● Siemens PLC + touch screen, friendly interface and easy operation

● Easy maintenance and economical cost

● 1-4 stage option

● No instrument gas required

● No special base and anchor bolt required

● Oil-free,Silicon-free

● No sealing gas required

● Low noise and low vibration

● Anti surge protection

● High efficiency scroll: the gas will enter the scroll directly for revolute type, but one vertical retrace will occur for involute type. The efficiency is increased by 2%

| Modello | Pressure(bar) | Flow range(m³/min) | Potenza del motore (kW) | Dimensions(L)(mm) | Dimensions(M)(mm) | Dimensions(H)(mm) | Peso (kg) |

|---|---|---|---|---|---|---|---|

| NXLC-300C | 0.6-9 | 24-48 | 132-263 | 2750 | 1500 | 1820 | 3800 |

| NXLC-600C | 0.6-12 | 45-82 | 248-450 | 3280 | 1850 | 2200 | 6300 |

| NXLC-900C | 0.6-12 | 76-122 | 400-640 | 3800 | 2000 | 2250 | 8160 |

| NXLC-1200C | 0.6-12 | 118-150 | 630-800 | 4200 | 2150 | 2350 | 11500 |

| NXLC-1500C | 0.6-16 | 118-228 | 760-1300 | 4200 | 2150 | 2350 | 12000 |

| NXLC-2000C | 0.6-16 | 186-310 | 980-1600 | 4600 | 2200 | 2500 | 17200 |

| NXLC-3000C | 0.6-16 | 268-438 | 1380-2250 | 5300 | 2300 | 2970 | 21500 |

| NXLC-4000C | 0.6-25 | 347-550 | 1800-2850 | 6000 | 4500 | 3500 | 40000 |

| NXLC-6500C | 0.6-25 | 530-920 | 2660-4540 | 8500 | 4200 | 4200 | 45000 |

| NXLC-10000C | 0.6-30 | 830-1660 | 4060-7950 | 12000 | 5000 | 5300 | 65000 |

| NXLC-20000C | 0.6-30 | 1780-3000 | 8990-15130 | 15000 | 6200 | 6000 | 80000 |

Nota:

Note sul numero di modello: “F” indica velocità fissa, “V” indica VSD. A causa delle velocità di rotazione potenzialmente diverse dei motori, le portate d'aria della velocità fissa rappresentano il minimo nell'intervallo (ovvero 30 kW 8 bar 5,67 m³/min), mentre il VSD può raggiungere il massimo a pieno carico.

Tensione standard in 380 V (+/-10%), 50 Hz +/-2% e disponibile per tensioni personalizzate 220/380/440/460 V/60 Hz.

In caso di altitudini elevate, temperature estreme, umidità eccessiva, forte esposizione alla polvere o qualsiasi altro ambiente operativo difficile, siamo in grado di offrire prodotti progettati su misura per soddisfare le vostre esigenze specifiche. È possibile personalizzare i prodotti in base alle vostre esigenze specifiche.

Core Component Highlights of theCentrifugal Air Compressors

Rotor

The high-speed rotor is dynamically balanced, and designed to resist vibration without thrust bearings. There is no relative sliding in the rotor transmission, and the gear drive system is highly reliable, with a design life of 35 years.

Impeller

● Aviation class high efficiency and high reliability titanium alloy impeller

● Anti-corrosion special coating impeller used for high corrosion industry

● Five-axis precision machining forging 3D flow back leaning design impeller, higher aerodynamic efficiency

● Splitter blade design for large flow

● Low flow loss and better adaptability for off-design conditions

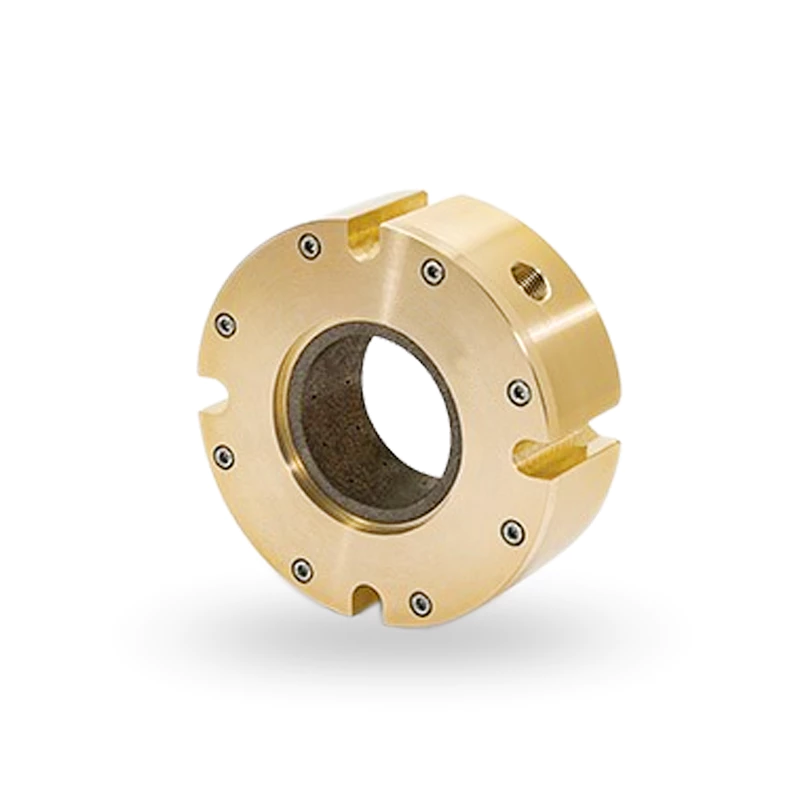

Bearings

● Tilting pad journal bearing realize high-speed and stable operation. Pad tilt will self-adjust when the bearing load changes.

● CC pad of high heat conductivity and high strength can decrease the bearing temperature and promote the stability of the rotor system.

Highly Reliable Cooler

● Straight tube design, no need to be pull out when maintaining, 90% maintenance time saved;

● No consumption parts and low maintenance fee;

● Larger design, high heat exchange efficiency, low water consumption and low pressure loss, about 1-2% energy saving;

● Gradual changing Cross design, perfect gas-liquid separation effect;

● Stainless steel backing board design, eliminating corrosion risk;

● No fastening parts, no risk of dameging the impellor by fallen parts;

● Supported by both side, eliminating the damage risk from resonance;

● Long life span drainer, no rusty, draining strongly and zero gas consumption.

Scatola ingranaggi

Horizontal split type for easy maintenance of the bearings and shaft seals.

Thrust collar instead of thrust bearings. Which makes the structure simpler and increase the transmission efficiency and reliability.

Local Control System

● The advanced Siemens PLC system +7” touch screen, friendly interface and easy opeartion;

● Options for auto dual, constant pressure control and self-balance control mode;

● All operating parameters can be displayed and setted;

● Features for various alarm and trip condition;

● Features anti-surge and surge prediction functions;

● Communication to DCS by DH+, Modbus, Profibus OR Ethernet.

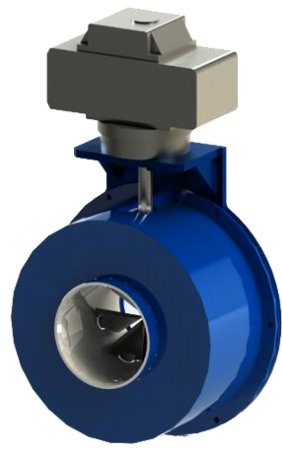

Inlet Guide Vane

The efficiency of compressor with IGV is 7-9% higher than that with butterfly valve, for IGV provides preswirl flow to the air taken into in the same direction as the impeller. Furthermore IGV can provide wider turn down rage and which is more smoothly during the adjusting period.

● Smoothly and high efficiency when adjusting;

● More safety and dust proof with cover;

● High reliability by fork type.

Air Seal

The gas & oil seal is labyrinth type, which has no contact to the shaft., no abrasion, long life, and low maintenance, no consumption of instrument air, and also, horizontal split makes easier maintenance.

Schema di installazione (normale)

Cerca

Tutti i prodotti

Contattaci

Cerchi la migliore soluzione di aria compressa per il tuo settore?

● Condividi le tue esigenze per una valutazione da parte di esperti (assistenza multilingue).

● Sviluppare soluzioni personalizzate, considerando opzioni quali livello IP, compressore e parti, lingua dello schermo, controllo remoto, aspetto, adattamento di tensione e temperatura, ecc.

● Avvio della produzione dopo la conferma dell'ordine (tempi di produzione standard: 20-25 giorni).

● Eseguire rigorosi test di qualità prima della spedizione.

● Assistenza tecnica a vita, ricambi originali e garanzia fino a 10 anni sul compressore.

Domande frequenti

What are the advantages of using a centrifugal air compressor?

Centrifugal air compressors are known for their high efficiency, reliability, and low maintenance requirements. They are ideal for applications that require a large volume of compressed air at a constant pressure, such as in industrial settings. The centrifugal air compressors are also quieter and more energy-efficient than other types of compressors.

How do I choose the right size centrifugal air compressor for my needs?

The size of the centrifugal air compressor you need depends on your specific application and the amount of compressed air required. Factors such as the size of your facility, the number of users, and the type of equipment being powered by the compressor all need to be considered. Consulting with a professional air compressor supplier or technician can help you determine the appropriate size and capacity for your needs.

How often does a centrifugal air compressor need maintenance?

Centrifugal air compressors generally require less maintenance than other types of compressors, but they still require regular upkeep to ensure optimal performance and longevity. A typical maintenance schedule includes regular oil and filter changes, inspection of bearings and seals, and checking for leaks or other issues. The frequency of maintenance will depend on factors such as usage, environment, and manufacturer recommendations. Consulting with a professional technician can help you establish an appropriate maintenance schedule for your compressor.

Controllare quindi il livello dell'olio e verificare che non vi siano perdite o ostacoli intorno alla macchina. Se si tratta di una macchina raffreddata ad acqua, aprire la valvola dell'acqua di raffreddamento e la pompa e verificare che la pressione dell'acqua sia normale. Infine, accendere la macchina e avviarla. Se è rimasta inattiva per un po' di tempo, avviarla alcune volte prima di farla funzionare in modo continuo per evitare inutili malfunzionamenti come il surriscaldamento o il sovraccarico.