Industri tekstil merupakan sektor yang sangat dinamis dan sangat bergantung pada berbagai peralatan dan mesin untuk memproduksi kain, pakaian, dan produk tekstil lainnya. Di antara peralatan penting tersebut adalah kompresor udara, yang memainkan peran penting dalam menyediakan udara terkompresi untuk berbagai aplikasi. Dalam artikel ini, kita akan membahas pentingnya kompresor udara dalam industri tekstil dan bagaimana kompresor udara sangat penting untuk memastikan efisiensi, produktivitas, dan kualitas dalam proses produksi tekstil.

Peran Kompresor Udara dalam Industri Tekstil

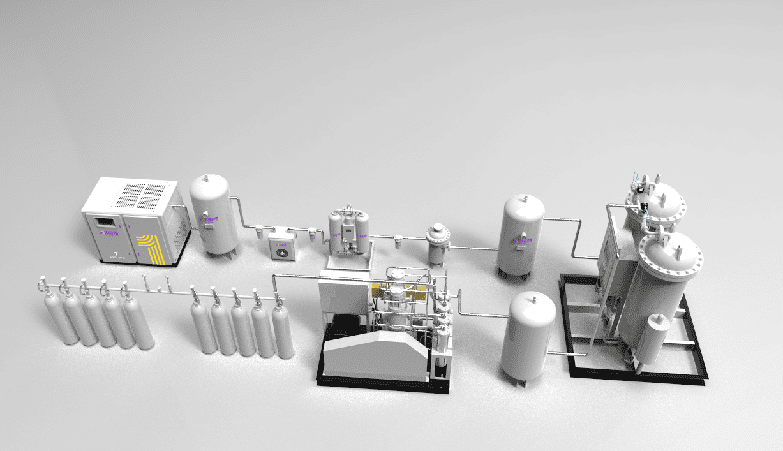

Kompresor udara sangat penting dalam industri tekstil untuk menyalakan berbagai alat dan peralatan pneumatik. Kompresor udara menghasilkan dan memasok udara bertekanan pada tekanan yang konsisten, yang sangat penting untuk mengendalikan pergerakan berbagai komponen dalam mesin tekstil. Beberapa aplikasi utama kompresor udara dalam industri tekstil meliputi

a. Proses Pemintalan: Kompresor udara menyediakan udara bertekanan untuk mesin-mesin pemintalan, mengendalikan proses-proses seperti penyusunan, pemintalan, dan penggulungan, memastikan produksi benang berkualitas tinggi.

b. Proses Penenunan: Pada mesin tenun, kompresor udara memberi daya pada jet udara dan perangkat rapier, memfasilitasi penenunan kain secara tepat dan efisien.

c. Pencetakan dan Pencelupan: Kompresor udara berperan penting dalam proses pencetakan dan pencelupan dengan menyediakan udara bertekanan untuk pengoperasian mesin pencelupan dan peralatan pencetakan.

d. Pembersihan dan Pengeringan: Kompresor udara digunakan untuk meniupkan udara untuk membersihkan serat, kain, dan permukaan mesin, serta mengeringkan produk jadi.

Efisiensi dan Penghematan Energi

Dalam industri tekstil yang kompetitif saat ini, efisiensi sangat penting untuk mempertahankan keunggulan kompetitif. Kompresor udara hemat energi dirancang untuk mengoptimalkan produksi udara dan mengurangi konsumsi daya. Fitur-fitur seperti variable speed drive (VSD) dan sistem kontrol cerdas memastikan bahwa kompresor beroperasi pada kapasitas yang diperlukan, mencegah pemborosan energi yang tidak perlu.

Keandalan dan Pengurangan Waktu Henti

Waktu henti yang tidak direncanakan dapat merugikan produsen tekstil. Memilih kompresor udara yang andal dan kuat dari produsen terkemuka dapat membantu meminimalkan waktu henti dan memastikan produksi yang berkelanjutan. Perawatan rutin dan servis tepat waktu sangat penting untuk menjaga kompresor dalam kondisi operasi puncak.

Kualitas dan Konsistensi

Kompresor udara memainkan peran penting dalam mempertahankan tekanan udara yang konsisten, memastikan kualitas produk yang seragam dan mengurangi variasi dalam produksi. Konsistensi ini sangat penting dalam proses seperti pencelupan dan pencetakan, di mana diperlukan kontrol yang tepat.

Pengurangan Kebisingan dan Pertimbangan Lingkungan

Di pabrik tekstil, di mana banyak mesin beroperasi, tingkat kebisingan dapat menjadi masalah bagi kesejahteraan pekerja. Kompresor udara dengan fitur pengurang kebisingan dan insulasi suara yang tepat dapat menciptakan lingkungan kerja yang lebih kondusif dan nyaman.

Kustomisasi dan Kemampuan Beradaptasi

Setiap fasilitas produksi tekstil memiliki persyaratan yang unik. Kompresor udara menawarkan fleksibilitas dalam hal penyesuaian dan kemampuan beradaptasi untuk memenuhi kebutuhan spesifik, memastikan kinerja terbaik untuk setiap proses.

Industri tekstil sangat bergantung pada kompresor udara untuk mendorong produktivitas, kualitas, dan efisiensi dalam berbagai proses produksi. Mulai dari pemintalan dan penenunan hingga pencelupan dan pencetakan, kompresor udara memberi daya pada operasi penting yang memungkinkan terciptanya tekstil berkualitas tinggi. Memilih kompresor udara yang tepat, dengan mempertimbangkan faktor-faktor seperti efisiensi, keandalan, pengurangan kebisingan, dan penyesuaian, dapat secara signifikan memengaruhi kinerja fasilitas produksi tekstil secara keseluruhan. Dengan berinvestasi pada kompresor udara berkualitas tinggi dan memastikan perawatan rutin, produsen tekstil dapat meningkatkan operasi mereka dan tetap kompetitif di pasar tekstil yang dinamis.