S-Series Two-stage Air Compressors

S-Series Two-stage Air Compressors

- Rated Pressure: 0.8-1.3 MPa, 8-13 bar, 116-188 psi

- Air Flow@ Outlet: 4.2-75.32 m³/min

- Power: 30-355 kW, 40-476 hp

Features of the two-stage air Compressor

● Self-developed variable speed technology which increases efficiency and offers energy savings.

● SKF Bearing , GHH RAND / Rotor Comp Air End(optional)

● Enhanced stability and reliability as well as cost-effectiveness.

● Reduce power consumption by around 35% compared to traditional frequency machines.

Core Component Highlights of the two-stage air Compressor

| Model No. / Drive Types | Power (kW/HP) | Rated Pressure (bar) | Air Flow @ Outlet(m³/min) | Dimensions (mm) | Weight (kg) | Air Outlet Pipe Diameter |

|---|---|---|---|---|---|---|

| NXS-30V NXS-30F | 30 / 40 | 8 | 5.67~6.3 | 1660*1085*1400 | 780 | DN40 |

| 10 | 4.9~5.4 | |||||

| 13 | 4.2~4.62 | |||||

| NXS-37V NXS-37F | 37 / 50 | 8 | 7.2~8 | 1660*1085*1440 | 820 | DN40 |

| 10 | 6.3~6.93 | |||||

| 13 | 5.4~5.94 | |||||

| NXS-45V NXS-45F | 45 / 60 | 8 | 8.2~9.5 | 2180*1360*1660 | 1800 | DN50 |

| 10 | 7.5~8.25 | |||||

| 13 | 6.5~7.15 | |||||

| NXS-55V NXS-55F | 55 / 75 | 8 | 12.0~12.83 | 2180*1360*1660 | 1860 | DN50 |

| 10 | 9.6~10.1 | |||||

| 13 | 8.36~8.8 | |||||

| NXS-75V NXS-75F | 75 / 100 | 8 | 16.1~17.1 | 2180*1360*1660 | 1960 | DN50 |

| 10 | 12.3~15.0 | |||||

| 13 | 10.6~12.22 | |||||

| NXS-90V NXS-90F | 90 / 120 | 8 | 19.1~20.1 | 2500*1600*1840 | 2800 | DN80 |

| 10 | 16.44~17.8 | |||||

| 13 | 14.0~14.77 | |||||

| NXS-110V NXS-110F | 110 / 150 | 8 | 21.6~25.0 | 2500*1600*1840 | 3100 | DN80 |

| 10 | 19.13~20.0 | |||||

| 13 | 16.19~17.5 | |||||

| NXS-132V NXS-132F | 132 / 175 | 8 | 26.4~28.4 | 2500*1600*1840 | 3300 | DN100 |

| 10 | 22.42~23.6 | |||||

| 13 | 19.7~21.6 | |||||

| NXS-160V NXS-160F | 160 / 215 | 8 | 32.3~34.64 | 3600*2100*2280 | 3800 | DN100 |

| 10 | 28.6~31.8 | |||||

| 13 | 24.32~26.33 | |||||

| NXS-185V NXS-185F | 185 / 250 | 8 | 34.5~39.1 | 3600*2100*2280 | 4100 | DN100 |

| 10 | 31.44~34.45 | |||||

| 13 | 26.79~29.63 | |||||

| NXS-200V NXS-200F | 200 / 270 | 8 | 40.7~44.0 | 3860*2100*2280 | 4800 | DN100 |

| 10 | 36.57~38.5 | |||||

| 13 | 31.63~33.3 | |||||

| NXS-220V NXS-220F | 220 / 300 | 8 | 45.6~48.77 | 3860*2100*2280 | 5100 | DN125 |

| 10 | 41.2~43.37 | |||||

| 13 | 32.6~36.1 | |||||

| NXS-250V NXS-250F | 250 / 335 | 8 | 50.5~54.8 | 3860*2100*2280 | 5600 | DN125 |

| 10 | 46.2~48.45 | |||||

| 13 | 40.5~42.95 | |||||

| NXS-280V NXS-280F | 280 / 375 | 8 | 56.6~59.0 | 4000*2280*2250 | 6300 | DN125 |

| 10 | 50.8~53.32 | |||||

| 13 | 42.5~45.26 | |||||

| NXS-315V NXS-315F | 315 / 420 | 8 | 62.2~65.97 | 4000*2280*2250 | 6500 | DN125 |

| 10 | 56.1~58.29 | |||||

| 13 | 47.3~49.72 | |||||

| NXS-355V NXS-355F | 355 / 475 | 8 | 74.2~75.32 | 4500*2280*2250 | 7700 | DN125 |

| 10 | 63.3~64.29 | |||||

| 13 | 52.2~54.1 |

Note:

Model number remarks: “F” as fixed speed, “V” as VSD. Due to the potentially different rotation speeds of motors, the air flow rates of fixed speed represent the minimum in the range (i.e 30kW 8 bar 5.67m³/min), while VSD can reach the maximum at full loading.

Standard voltage in 380V (+/-10%), 50Hz +/-2% and available for customized voltage 220/380/440/460V/60Hz.

In cases of elevated altitudes, extreme temperatures, excessive humidity, heavy dust exposure, or any other challenging operational environments, we can offer tailored product designs to meet your specific needs. Customization is available to align with your unique requirements.

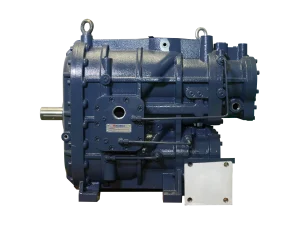

Air End

● Adopt two-stage independent compression ;

● The pressure ratio is equal over both stages as well as having a lower compression speed, which helps improve volumetric efficiency;

● Oil mist spray cooling is used between the stages to make the entire compression process close to isothermal compression and improve the compression insulation efficiency;

● The two-stage rotors are directly driven by the bevel gear respectively, and the compression transmission efficiency is high;

● The large diameter and low speed of the rotors reduce stress on the bearings, thus lengthening their life span as well as any other components.

High- Protection Level Motor

The main motor is an IP55 high-efficiency energy-saving permanent magnet motor carefully selected according to the application of the air compressor. (other IP level available)

All meet the national energy efficiency standards, F-class insulation, B-class temperature rise, effectively prevent the entry of dust,SKF heavy-duty bearings ensure continuous trouble-free operation for a long time.

Ultra-Quiet Centrifugal Cooling Fan

● Ultra-quiet large air volume, frequency conversion cooling fan;

● Low loss, low noise, low power consumption;

● High heat transfer rate, quiet and efficient.

Customized large cooling system

The cooling system is designed to keep the temperature at a constant level. Its features include an increased radiator surface area with rust and corrosion resistant coatings, as well as a low oil temperature which prevents carbon deposits and high-temperature occurrences.

Additionally, the use of large variable frequency fans or centrifugal fans in units over 75 kW ensures even heat distribution, low noise levels, and large air volume.

Installation Diagram for Two-stage Screw Compressor(Variable Speed Rotary Screw Type)

Search

All Product

Contact Us

Looking for the Best Compressed Air Solution for your industry?

● Share your requirements for expert evaluation (multilingual support).

● Develop customized solution, considering options such as IP level, air end and parts, screen language, remote control, appearance, voltage and temperature adaptation, etc.

● Start production after order confirmation (standard production time: 20-25 days).

● Conduct rigorous quality testing before shipping.

● Lifelong technical support, original maintenance parts support, and up to 10-year warranty on the air end.

Frequently Asked Questions

What is the difference between Single-stage and Two-stage air compressor?

Low Pressure Two-stage VSD Screw Air Compressor is a type of air compressor that uses two stages of compression to produce compressed air. It is equipped with a Variable Speed Drive (VSD) system that allows for energy-efficient operation and can adjust the compressor’s speed to match the air demand. This type of compressor is commonly used in industries such as automotive, food and beverage, and pharmaceuticals.

How does a two-stage air compressor work?

A two-stage air compressor works by compressing air in two stages. In the first stage, air is compressed to an intermediate pressure and then sent to a second cylinder where it is compressed to the final desired pressure. This allows for higher efficiency and greater power output compared to a single-stage compressor.

What are the tips for starting up the two-stage air compressor?

First, check the refrigerant pressure and ensure that the cold dryer and suction dryer are working properly. Also, make sure that the air compressor’s storage tank and filters are draining properly. Then, open the valves between the storage tank, dryers, filters, and the air compressor to ensure smooth airflow.

Next, check the oil level and look for any leaks or obstacles around the machine. If it’s a water-cooled machine, open the cooling water valve and pump, and confirm that the water pressure is normal. Finally, turn on the power and start the machine. If it has been idle for a while, start it a few times before running it continuously to avoid unnecessary malfunctions such as overheating or overload.