Air Bearing Turbo Blower

Air Bearing Turbo Blower

Pressure (KPa): 40 – 120

Power (kW): 5.5 – 600

Outlet Pipe Diameter: DN80 – DN500

Features of the Air Bearing Turbo Blower

High Efficiency Energy Saving: Compared to conventional “Roots Blowers,” power consumption is reduced by over 30%.

Simple Operation Intelligent Control:Equipped with an intuitive touch screen, ensuring easy and convenient operation.

Low Noise Vibration-Free: Operating at less than 80 dB, with no vibration, eco-friendly, and no foundation support required.

Oil-free Maintenance-free:100% oil-free, preventing secondary pollution, with no need for regular maintenance or bearing replacement.

Compact Design Easy Installation: Ensure no complicated installation and easy setup.

Long Lifetime Stable Performance:Using advanced air suspension bearing technology, designed for over 20 years of use, with stable efficiency and no performance decline throughout the lifetime.

| Model Free Air Delivery Parameter | FAD (m³/min) | Pressure(KPa) | Power (kW) | Outlet Pipe Diameter | Size (mm) | Weight (Kg) | ||||||||||

| 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | L | W | X | |||||

| NXAB-5.5 | m³/min | 5.3 | 4.3 | 3.6 | 3 | 2.5 | / | / | / | / | 5.5 | DN80 | 850 | 500 | 950 | 130 |

| NXAB-7.5 | 7.4 | 5.6 | 5 | 4.2 | 3.5 | / | / | / | / | 7.5 | 150 | |||||

| NXAB-11 | 10.9 | 8.8 | 7.3 | 6.6 | 5.2 | / | / | / | / | 11 | 185 | |||||

| NXAB-15 | 15 | 12 | 10 | 8.9 | 7.2 | / | / | / | / | 15 | DN100 | 1000 | 660 | 1100 | 200 | |

| NXAB-18.5 | 19 | 15 | 13 | 11 | 9 | / | / | / | / | 18.5 | 220 | |||||

| NXAB-22 | 23 | 19 | 16.5 | 14 | 11 | 11 | / | / | / | 22 | 250 | |||||

| NXAB-30 | 34 | 28 | 24 | 20 | 17 | 16 | 15 | / | / | 30 | DN200 | 1200 | 810 | 1400 | 300 | |

| NXAB-37 | 43 | 35 | 30 | 27 | 23 | 21 | 19 | / | / | 37 | 330 | |||||

| NXAB-45 | 53 | 43 | 37 | 34 | 29 | 26 | 24 | / | / | 45 | 350 | |||||

| NXAB-55 | 65 | 53 | 46 | 42 | 36 | 32 | 30 | 28 | 26 | 55 | 400 | |||||

| NXAB-75 | 89 | 73 | 66 | 58 | 51 | 45 | 41 | 39 | 36 | 75 | 410 | |||||

| NXAB-90 | 108 | 88 | 80 | 70 | 62 | 54 | 50 | 47 | 44 | 90 | DN350 | 1500 | 1060 | 1450 | 450 | |

| NXAB-110 | 133 | 108 | 98 | 85 | 77 | 67 | 62 | 58 | 54 | 110 | 500 | |||||

| NXAB-132 | 160 | 130 | 118 | 102 | 93 | 81 | 75 | 70 | 65 | 132 | 550 | |||||

| NXAB-160 | 195 | 155 | 144 | 124 | 113 | 99 | 92 | 85 | 79 | 160 | 600 | |||||

| NXAB-185 | 227 | 185 | 167 | 144 | 131 | 115 | 107 | 99 | 91 | 185 | 700 | |||||

| NXAB-200 | 246 | 201 | 181 | 155 | 142 | 125 | 116 | 108 | 99 | 200 | 800 | |||||

| NXAB-250 | 310 | 254 | 228 | 196 | 177 | 157 | 146 | 136 | 125 | 250 | DN400 | 1990 | 1300 | 1850 | 1600 | |

| NXAB-300 | 372 | 308 | 274 | 236 | 213 | 188 | 176 | 163 | 151 | 300 | 1700 | |||||

| NXAB-400 | 497 | 412 | 367 | 316 | 285 | 253 | 236 | 219 | 205 | 400 | DN500 | 2530 | 2400 | 2070 | 2400 | |

| NXAB-500 | 622 | 518 | 459 | 396 | 356 | 316 | 295 | 274 | 256 | 500 | 3000 | |||||

| NXAB-600 | 745 | 620 | 550 | 475 | 430 | 380 | 355 | 330 | 308 | 600 | 3200 | |||||

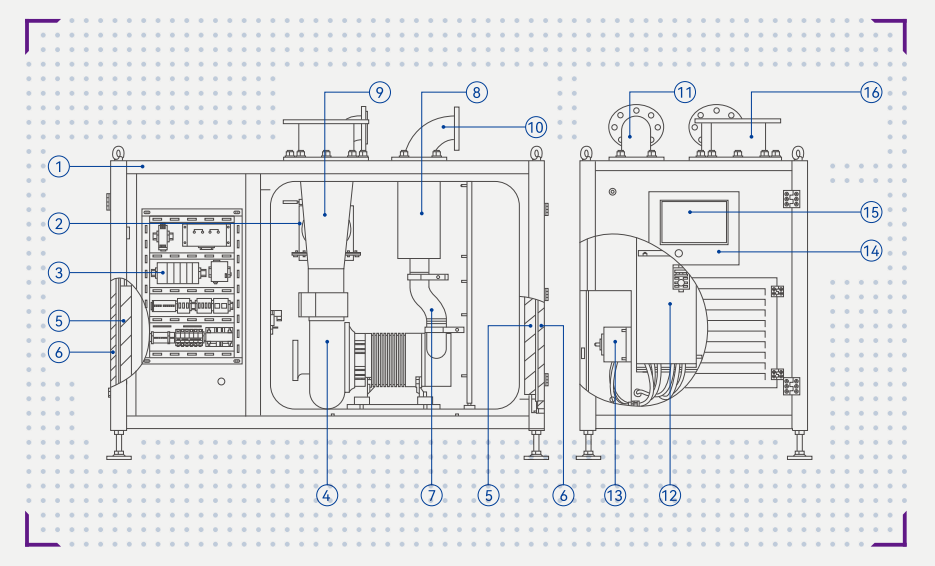

Product Structure of the Air Bearing Turbo Blower

Structure of the air bearing turbo blower

The air bearing turbo blower is mainly composed of a turbo air end, a frequency inverter,a controller, pipelines and a cabinet.

① Cabinet

② Vent Valve

③ Control Module

④ Turbo Air End

⑤ Secondary Filter Cotton

⑥ Primary Filter Cotton

⑦ Connecting Hose

⑧ Cooling Silencer

⑨ Exhaust Conical Pipe

⑩ Heat Dissipation Outlet Pipe

⑪ Vent Outlet Pipe

⑫ Inverter

⑬ Circuit Breaker

⑭ Emergency Stop Button

⑮ Touch Screen

⑯ Discharge Outlet Pipe

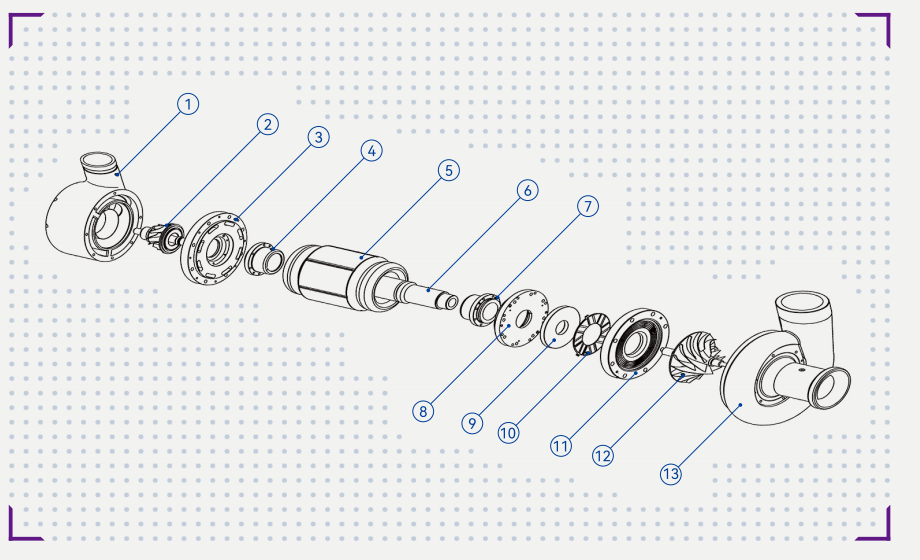

Structure of the turbo air end

The turbo air end is composed of a permanent magnet synchronous motor, a three-dimensional flow impeller, a volute,a dynamic pressure air bearing, and a cooling impeller.The motor is directly connected to the impeller, and there is no transmission loss.

① Heat Dissipation Volute

② Heat Dissipation Impeller

③ Rear Mount

④ Rear Bearing

⑤ Motor

⑥ Motor Shaft

⑦ Front Bearing

⑧ Front Mount

⑨ Thrust Plate

⑩ Thrust Bearing

⑪ Front Thrust Mount

⑫ Impeller

⑬ Volute

Search

All Product

Contact Us

Application of the Air bearing Turbo Blower

Designed for continuous and reliable operation, the air bearing turbo blower is commonly applied in electric power, steel smelting, pneumatic Convey, Chemical industry, Cement Production, and Sweage Disposal. The following images illustrate its performance in real-world application environments.

Looking for the Best Compressed Air Solution for your industry?

● Share your requirements for expert evaluation (multilingual support).

● Develop customized solution, considering options such as IP level, air end and parts, screen language, remote control, appearance, voltage and temperature adaptation, etc.

● Start production after order confirmation (standard production time: 20-25 days).

● Conduct rigorous quality testing before shipping.

● Lifelong technical support, original maintenance parts support, and up to 10-year warranty on the air end.

Frequently Asked Questions

What makes the Air Bearing Turbo Blower more energy-efficient than conventional blowers?

Our blower uses advanced air bearing technology, reducing friction and mechanical losses. Compared to traditional Roots Blowers, it lowers power consumption by over 30%, saving operational costs significantly.

Is the blower easy to operate?

Yes. The blower is equipped with an intuitive touch screen and intelligent control system, allowing operators to monitor and adjust parameters easily without complex training.

How noisy is the Air Bearing Turbo Blower?

The blower operates at less than 80 dB and produces virtually no vibration. It is eco-friendly, quiet, and does not require a special foundation for installation.