Oil-free Screw Blower

Oil-free Screw Blower

- FAD: 1.8–196.4 m³/min

- Exhaust Pressure: 40–200 kPa

- Operating Speed: 1800–6000 rpm

- Noise Level: <85 dB(A)

Features of the oil—Free Screw Blower

High Efficiency & Reliability:

- 15–30% energy savings vs. Roots blowers, stable flow with no surge.

- Low pressure pulsation and steady exhaust

Integrated Enclosure Design

- No foundation required, easy installation.

- Zero-leakage pipe sealing with forced-circulation lubrication and cooling for enhanced reliability.

Oil-Free & Low Noise

- Spiral and carbon ring seals ensure 100% oil-free air.

- Smooth airflow with noise below 85 dB(A).

| Model No. | Exhaust Pressure (kPa) | Speed(rpm) | FAD(m³/min) | Motor Power (kW) | Exhaust Temperature | Inlet Oil Volume (L) | Outlet Oil Volume (L) |

|---|---|---|---|---|---|---|---|

| NXGF-2.4Y | 40-100 | 2000-3000 | 1.8-2.4 | 3.4-8.3 | 60-110 | 1.52 | 1.44 |

| NXGF-4.8Y | 40-100 | 2000-3000 | 2.8-4.8 | 3.9-10.8 | 60-110 | 1.53 | 1.44 |

| NXGF-8.3Y | 40-100 | 2000-3000 | 4.1-8.3 | 5.0-17.0 | 60-110 | 1.8 | 1.1 |

| NXGF-11.3Y | 40-100 | 2000-3000 | 7.0-11.3 | 10.3-26.1 | 60-110 | 1.88 | 2.42 |

| NXGF-14.1Y | 40-100 | 2000-3000 | 7.7-14.1 | 9.3-29.2 | 60-110 | 2.3 | 22 |

| NXGF-19.1Y | 40-100 | 2000-3000 | 10.2-19.1 | 11.6-37.3 | 60-110 | 2.3 | 22 |

| NXGF-23.5Y | 40-100 | 2000-3000 | 12.3-23.5 | 15.1-45.0 | 60-110 | 2.98 | 3.74 |

| NXGF-30.9Y | 40-100 | 2000-3000 | 17.6-30.9 | 17.5-59.4 | 60-110 | 4 | 3.8 |

| NXGF-40.2Y | 40-100 | 2000-3000 | 22.9-40.2 | 22.6-68.3 | 60-110 | 4 | 3.8 |

| NXGF-47.2Y | 40-100 | 2000-3000 | 27.7-47.2 | 36.5-90.2 | 60-110 | 4.5 | 5.3 |

| NXGF-59.6Y | 40-100 | 1800-3000 | 35.0-59.6 | 47.8-108.7 | 60-110 | 4.5 | 5.3 |

| NXGF-73.6Y | 40-100 | 1800-3000 | 43.0-73.6 | 40.1-131.2 | 60-110 | 8.3 | 7.3 |

| NXGF-87.7Y | 40-100 | 1800-3000 | 47.8-87.7 | 47.2-164.4 | 60-110 | 8.3 | 7.3 |

| NXGF-113.1Y | 40-100 | 1800-3000 | 56.5-113.1 | 77.0-217.6 | 60-110 | 8.26 | 13.16 |

| NXGF-1282Y | 40-100 | 1800-3000 | 64.0-128.1 | 90.4-231.8 | 60-110 | 8.26 | 13.16 |

| NXGF-132.1Y | 40-100 | 1800-3000 | 72.2-132.1 | 72.3-246 | 60-110 | 15.6 | 16.4 |

| NXGF-167.7Y | 40-100 | 1800-3000 | 93.8-167.7 | 93.3-292.0 | 60-110 | 15.6 | 16.4 |

| Model No. | Exhaust Pressure (kPa) | Speed(rpm) | FAD(m³/min) | Motor Power (kW) | Exhaust Temperature | Inlet Oil Volume (L) | Outlet Oil Volume (L) |

|---|---|---|---|---|---|---|---|

| NXGF-6.8S | 100-150 | 3600-6000 | 3.0-6.8 | 9.5-23.0 | 101.6-164.4 | 60 | 50-80 |

| NXGF-9.4S | 100-150 | 3500-6000 | 4.0-9.4 | 11.7-27.8 | 103.2-161.3 | 60 | 50-80 |

| NXGF-23.18 | 100-150 | 2800-5000 | 11.2-23.1 | 24.2-67.1 | 102.2-152.1 | 60 | 60-80 |

| NXCF-21.1S | 160-200 | 3000-5000 | 10.5-21.1 | 41-77.5 | 144.6-185.0 | 60 | 50-80 |

| NXGF-315S | 100-150 | 2800-5000 | 16.3-31.5 | 33.0-85.4 | 102.2-147.7 | 60 | 60-80 |

| NXCF-28.9S | 160-200 | 3000-5000 | 14.8-28.9 | 48.5-93.1 | 140.8-184.0 | 60 | 50-80 |

| NXGF-458S | 100-150 | 2600-4900 | 22.6-45.8 | 43.9-108.0 | 104.6-149.5 | 60 | 60-80 |

| NXCF-42.1S | 160-200 | 2800-4900 | 20.5-45.1 | 63.9-132.3 | 155.0-193.0 | 60 | 60-100 |

| NXGF-56.6S | 100-150 | 2600-4800 | 28.2-56.6 | 54.4-135.0 | 104.6-149.5 | 60 | 60-80 |

| NXGF-53.6S | 160-200 | 2800-4900 | 28.1-53.6 | 78.2-162.0 | 160.8-191.1 | 60 | 60-100 |

| NXCF-65.3S | 100-150 | 2000-3300 | 35.0-65.3 | 67.8 ·154.8 | 101-146 | 60 | 60-80 |

| NXGF-64.6S | 160-200 | 2200-3300 | 36.6-64.6 | 112.6-196.7 | 178-188 | 60 | 50-70 |

| NXCF-98.9S | 100-150 | 2000-3300 | 54.2-98.9 | 112.7-245.0 | 101-146 | 60 | 60-80 |

| NXGF-196.48 | 100-150 | 1800-3100 | 101.2-196.4 | 210.0-474.8 | 88-139 | 60 | 70-120 |

Why Choose the oil—Free Screw Blower?

The oil-free screw blower operates with a pair of intermeshing rotors that rotate synchronously, drawing air through the inlet, progressively compressing it, and discharging it through the outlet. With precisely controlled clearances between the rotors and casing, the system eliminates the need for lubricating oil inside the compression chamber. This design ensures clean, oil-free air while delivering stable and efficient compression throughout the entire working cycle.

Unlike a conventional Roots blower—where suction ends and the trapped air volume remains constant until external back pressure forces compression—the oil-free screw blower performs internal compression from the moment suction ends. This continuous, progressive compression improves energy consumption and efficiency. Compared with Roots blowers, the oil-free screw blower offers higher efficiency, lower noise, better reliability, allows higher rotor tip speed, and achieves higher discharge pressure.

Labyrinth Silencer

The labyrinth silencer uses multiple baffles and reflection channels to reduce airflow and mechanical noise. It significantly lowers operating noise while keeping airflow smooth and pressure loss minimal, ensuring blower efficiency is not affected.

High-Efficiency Motor

The IE4 permanent magnet motor delivers 96%–97% efficiency. It features F-class insulation, B-class temperature rise design, IP55 protection, and imported SKF bearings. This ensures smooth operation, low noise, long service life, and stable performance in harsh industrial environments.

Intelligent Control System

The intelligent control system provides visual display of operation status, operating data, and fault alarms. It supports online monitoring of pressure, power, and temperature fluctuations. Multi-language customization enables intuitive, fast, and convenient operation.

High-Efficiency Inverter

Using PM VSD technology with 0–100% stepless speed regulation, the inverter ensures efficient performance under full load or fluctuating air consumption conditions.

High-Efficiency Air End

The air end adopts an optimized rotor profile and advanced coating technology to achieve higher efficiency and longer service life. It uses internationally recognized bearings and high-precision synchronous gears for improved reliability and durability. Unique lubrication and oil drainage channels enhance cooling and lubrication performance. Labyrinth and carbon ring sealing provide 100% oil-free isolation between the compression chamber and lubrication chamber with a simpler structure.

Search

All Product

Contact Us

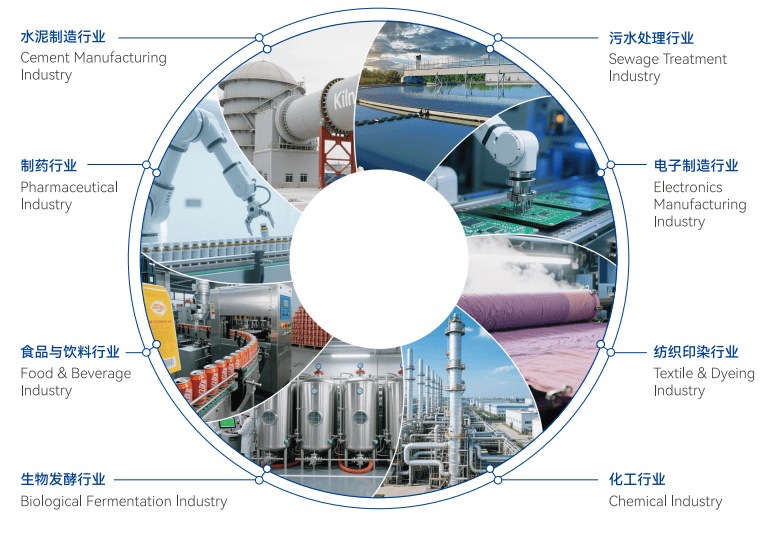

Application of the oil-Free Screw Blower

- Cement Manufacturing Industry:Provides stable oil-free airflow for material conveying, combustion support, and process aeration.

- Pharmaceutical Industry:Ensures clean, contamination-free air for controlled processes and fermentation systems.

- Food & Beverage Industry:Delivers hygienic oil-free air for mixing, aeration, and safe production environments.

- Biological Fermentation Industry:Supports consistent airflow for fermentation processes requiring stable oxygen transfer.

- Sewage Treatment Industry:Supplies efficient aeration for biological treatment tanks and oxidation systems.

- Electronics Manufacturing Industry:Provides clean compressed air for precision cleaning, drying, and pneumatic operations.

- Textile & Dyeing Industry:Ensures stable airflow for dyeing, drying, and process ventilation.

- Chemical Industry:Supports chemical processes requiring reliable and contamination-free air supply.

Looking for the Best Compressed Air Solution for your industry?

● Share your requirements for expert evaluation (multilingual support).

● Develop customized solution, considering options such as IP level, air end and parts, screen language, remote control, appearance, voltage and temperature adaptation, etc.

● Start production after order confirmation (standard production time: 20-25 days).

● Conduct rigorous quality testing before shipping.

● Lifelong technical support, original maintenance parts support, and up to 10-year warranty on the air end.

Frequently Asked Questions

How does the oil-free screw blower operate without lubricating oil?

The blower uses a pair of intermeshing rotors with precise clearances between the rotors and casing. This design allows progressive compression of air while maintaining 100% oil-free airflow.

What are the advantages compared to a conventional Roots blower?

Compared with Roots blowers, the oil-free screw blower provides higher efficiency, lower noise, better reliability, allows higher rotor tip speed, and achieves higher discharge pressure.

Can the blower operate under harsh industrial conditions?

Yes. Equipped with an IE4 permanent magnet motor, IP55 protection, and imported SKF bearings, the blower ensures stable, low-noise performance and long service life even in demanding industrial environments.