Portable PSA Nitrogen Generator

Portable PSA Nitrogen Generator

- Nitrogen Capacity: 3–20 Nm³/h

- Air Consumption: 0.4–4.33 m³/min

- Nitrogen Outlet Size: DN15

- Air Inlet Pressure: 8–10 Bar

- Nitrogen Outlet Pressure: 1–6.5 Bar

Features of the Portable PSA Nitrogen Generator

- Portable and space-saving: Small size and light weight, it can be easily moved or deployed in narrow places (such as laboratories and workshop corners), without fixed installation, suitable for temporary or decentralized.

- Flexible adaptation: Covering various scenarios such as medical, food packaging, electronic welding, labo ratories, etc., the nitrogen purity can also be customized (such as 95%~99.999%) to meet different industry standards.

- Simple Operation: No need for complex debugging, rapid nitrogen production after power-on (usually 5 to 30 minutes to reach standard purity), simple user interface, suitable for non-professional operation.

- Maintenance-free or low maintenance: Adopting integrated design, key components have a long life, and only simple cleaning is required daily to reduce downtime.

| Model | Purity(%) | Nitrogen Capacity (Nm³/h) | Air Consumption (m³/min) | Air Inlet | Nitrogen Outlet | Air Inlet Pressure(Bar) | Nitrogen Outlet Pressure (Bar) |

|---|---|---|---|---|---|---|---|

| NXN-3 | 99.9 | 3 | 0.4 | DN25 | DN15 | 8-10 | 1-6.5 |

| 99.99 | 0.8 | ||||||

| NXN-5 | 99.9 | 5 | 0.6 | DN25 | DN15 | 8-10 | 1-6.5 |

| 99.99 | 1 | ||||||

| NXN-10 | 99 | 10 | 0.5 | DN25 | DN15 | 8-10 | 1-6.5 |

| 99.5 | 0.58 | ||||||

| 99.9 | 0.75 | ||||||

| 99.99 | 0.85 | ||||||

| 99.999 | 2.17 | ||||||

| NXN-20 | 99 | 20 | 1 | DN25 | DN15 | 8-10 | 1-6.5 |

| 99.5 | 1.17 | ||||||

| 99.9 | 1.5 | ||||||

| 99.99 | 1.7 | ||||||

| 99.999 | 4.33 |

Note:The data in this table are based on 8 Bar feed air, 20℃ ambient temperature, 0 m gauge, and 80% relative humidity.

The data provided in this sample is for reference only.

Core Component Highlights of the Portable PSA Nitrogen Generator

Nitrogen analyzer

●Temperature Range: Ambient to 450 °C / 842 °F;

●Temperature Stability: ± 0.5 °C;

●Temperature Precision: ± 0.5 °C;

●Process nitrogen anlyzer ,Core components imported from Germany.

Pneumatic valves

●The valve body adopts a one-piece design to avoid possible leakage caused by the connection of the middle flange;

●The valve stem and the spool are connected by splines, which has good alignment, large bearing torque, eliminates the gap, and improves the valve adjustment accuracy;

●The upper and lower valve stems are fixed by self-lubricating bearings, which has high rotation accuracy and good transmission stability.

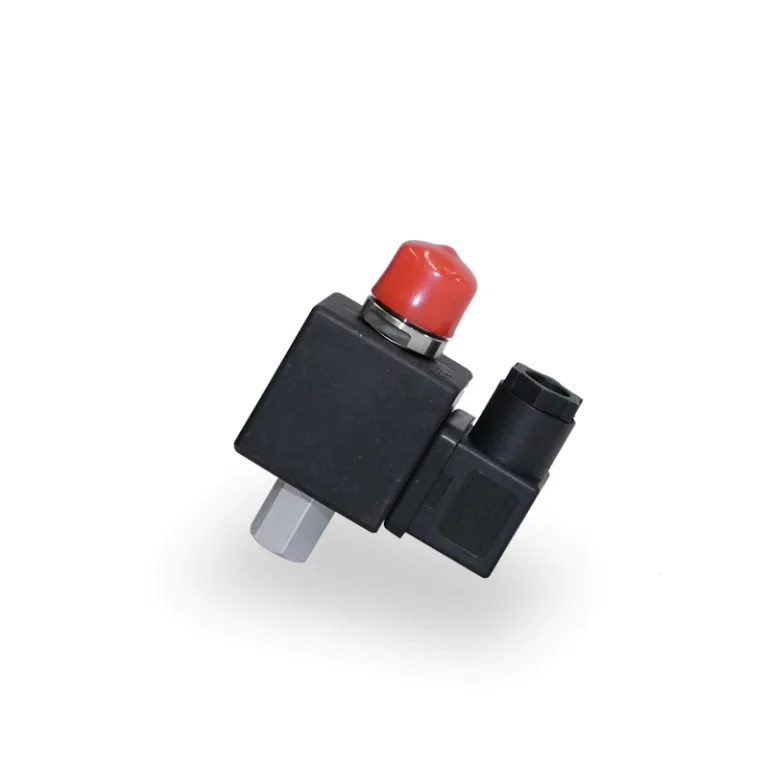

Solenoid valves

●Patented technology products, can last for a long time to power on for 365 days to replace normally open valves;

●Adopt diaphragm structure, low requirements for medium cleanliness;

●The valve flow coefficient is 10% higher than that of ordinary valves;

●Adopt special sealing structure and imported synthetic rubber seal without leakage.

Search

All Product

Contact Us

Regular installation Flow

Looking for the Best Compressed Air Solution for your industry?

● Share your requirements for expert evaluation (multilingual support).

● Develop customized solution, considering options such as IP level, air end and parts, screen language, remote control, appearance, voltage and temperature adaptation, etc.

● Start production after order confirmation (standard production time: 20-25 days).

● Conduct rigorous quality testing before shipping.

● Lifelong technical support, original maintenance parts support, and up to 10-year warranty on the air end.

Frequently Asked Questions

How long does the Portable PSA Nitrogen Generator take for the generator to produce nitrogen after startup?

The system typically reaches the required purity within 5–30 minutes after powering on. No complex debugging is needed, making it suitable for non-professional users.

Does the PSA Nitrogen Generator take for the generator require fixed installation?

No. The generator is portable and space-saving, designed for flexible movement. It can be placed in narrow spaces such as laboratories, workshop corners, or temporary working sites without any fixed installation.